Description

SPECIFICATIONS

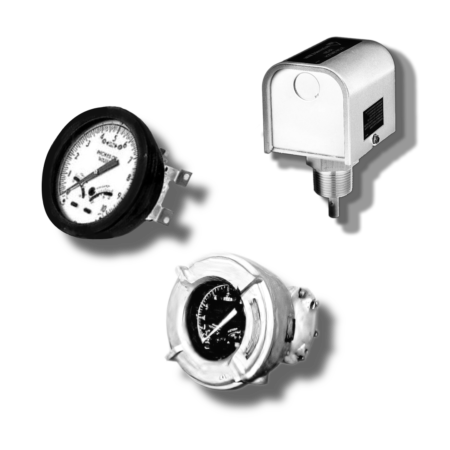

Model 199

The linear motion of the bellows is transformed into angular rotation when transferred by the push wheel to the torque tube shaft and this mechanical motion activates the process monitoring device system. The process monitoring tool linked to the torque tube assembly may be an indicator, switch, receiver, recorder, or other process control unit.

The pulsation dampener regulates the fill-liquid flow between the elevated and low-pressure bellows with an externally controlled pulsation dampener needle valve. Restricting liquid flow decreases the impacts of pulsation. In apps where pulsation is not an issue, the needle valve is put to the full open position.

WHY Controls Supply Chain

- • Over 50 years of industry knowledge

- • Fast customer service; response within 15 minutes

- • Best price quality ratio

- • We facilitate the total procurement, purchase and engineering process of our customers

PARTS