Description

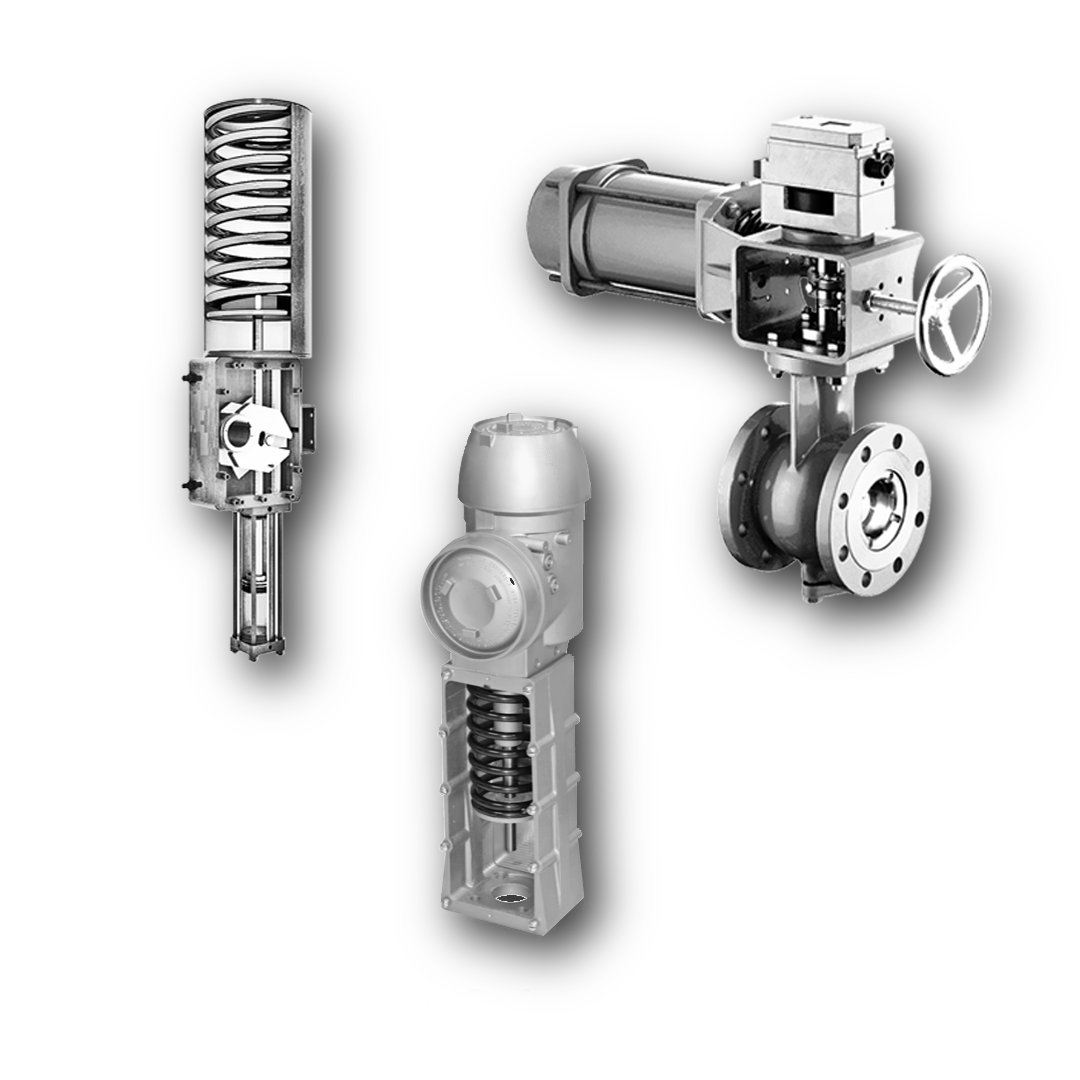

The Model J actuator handles gate valves with working pressures up to 10,000 psi and diameters ranging from 5” to 10”. (689 bar). These actuators are offered with a 5” or 7” piston to satisfy the application’s control pressure requirements. External safety release mechanism prevents the actuator from overpressurization on Model J hydraulic actuators. To stroke big-bore valves in limited spaces, the profile is short and compact. The Quick-Disconnect function allows the actuator to be removed without depressurizing the valve, resulting in significantly less downtime and lost productivity. The position of the gate valve is visually indicated by the rising stem. Actuators are electric-powered devices that allow pipeline operators to operate valves. Electric, air (pneumatic), or flow power (hydraulic), which in our instance is gasoline or gas, can all be used. Two types of actuators are available: temporary and rotating. Gas-over-oil actuators move the mechanics of the actuator by suspending the high pressure gas in the pipeline with a hydraulic fluid. Double-acting gas-over-oil actuators are the only ones that can be used. A power source provides electricity to electric actuators like a battery. Precision control of product flow through valves is critical in the oil, gas, and petrochemical industries, and the valve actuator is responsible for this modulation.