Description

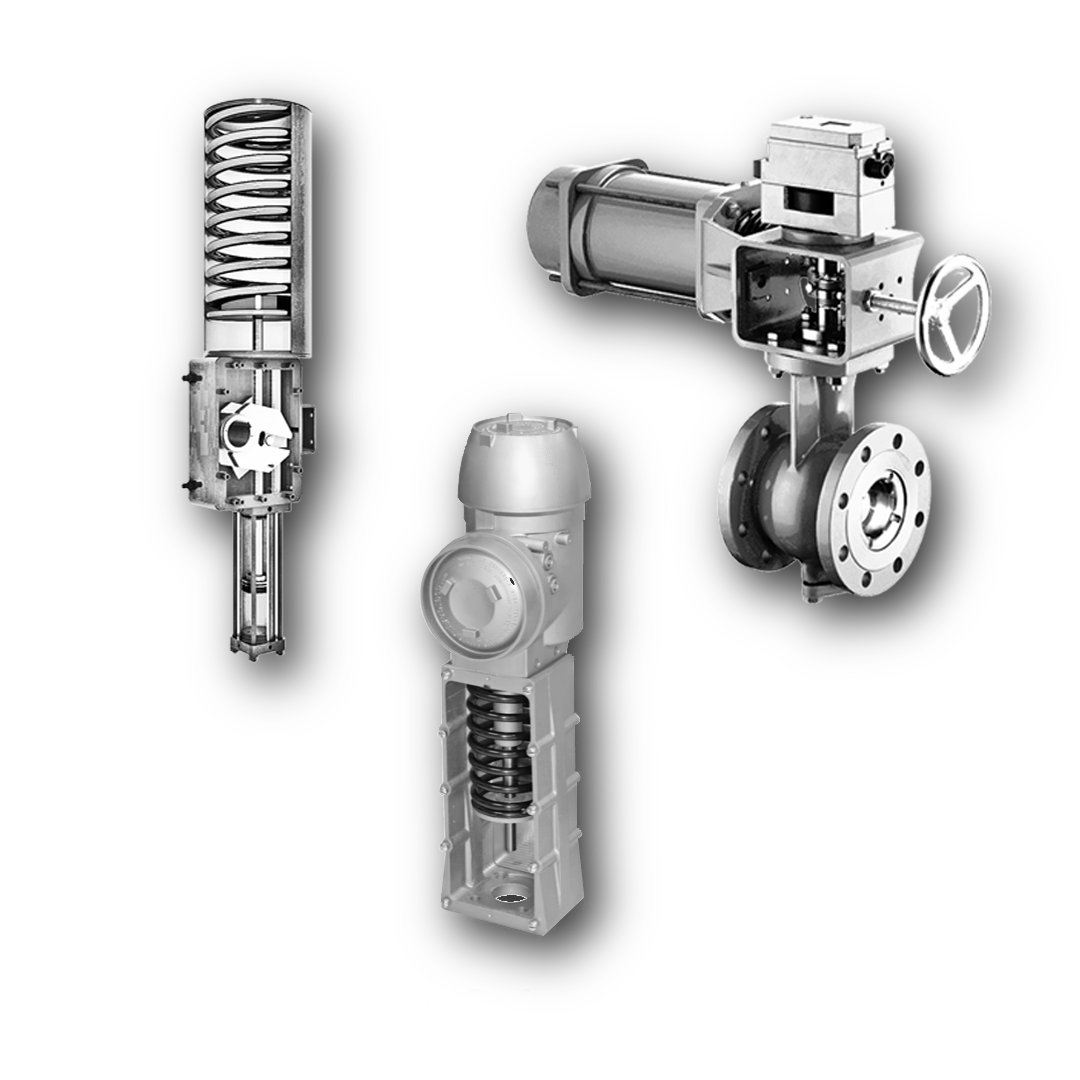

Actuators are devices that enable pipeline operators to control valves using an electricity source. It is possible to utilize electric, air (pneumatic) or flow power (hydraulic) which is, in our case, petrol or gas. Temporary and rotational actuators are split into two kinds. By suspending the high pressure gas in the pipeline via a hydraulic fluid, gas-over-oil actuators move the mechanics of the actuator. It is only possible to have double-acting gas-over-oil actuators. Electric actuators such as a battery are powered by a power source. In oil, gas and petrochemical sectors, precision control of product flow through valves is important and the modulation is reliant on the valve actuator. The key components of this system must work consistently and safely in the most severe circumstances, including extremely high and low temperatures, drought or high river conditions, isolated desert and Arctic sites and chemical corrosive effects, high moisture or long-lasting salt. In potentially explosive settings, explosion protection is required and, in particular, flammable operation is crucial. The actuator acts as a crucial connection between the process and the supervisory control system, which makes it possible to easily integrate into any DCS system in the plant network.