Description

SPECIFICATIONS

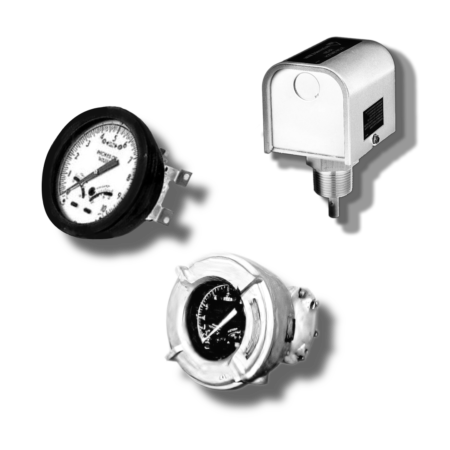

763A Gage Pressure Transmitter

To run the transmission circuit, a controlled DC energy distribution is needed. The 763A transmitter’s electronic components are located in a rough, pressurized box to avoid steam intrusion. An EGS ® quick-disconnect plug ensures the stability of electrical links and particularly engineered radiation-resistant electronic components minimize degradation connected with nuclear radiation exposure. A normal enclosure cover allows simple entry to zero-span adaptation checks.A wire is welded to the Bourdon tube’s loose bottom and to a strain gauge frame.

Pressure fed to the Bourdon tube appears to bend the pipe, which splits the strain gauge column proportionally. Motion of the beam’s loose side transfers pressure to one strain gage, expanding its strength and compression to the other, reducing its strength. The two gauges create a bridge circuit and the transmitter electronics condition the bridge yield stream and convert it to a 4-to 20-mA or 10-to 50-mA yield stream. The input wave is transferred to distant transmitting equipment via a two-wire transmission loop.

WHY Controls Supply Chain

- • Over 50 years of industry knowledge

- • Fast customer service; response within 15 minutes

- • Best price quality ratio

- • We facilitate the total procurement, purchase and engineering process of our customers

PARTS