Description

SPECIFICATIONS

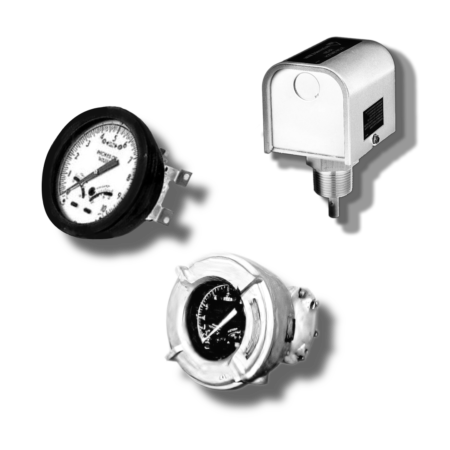

753 Explosion-proof Electronic Transmitter

For the Model 753 transmitters, the mechanical actuating device is a dual bellows assembly enclosed by a set of two pressure housings. The structure comprises of two interconnected bellows, a center block, overrange valves, a temperature compensator, a strain gage installation, and distance springs. The inner volume of the bellows and center block is filled and sealed with a clean, non-corrosive, non-conductive liquid with a low freezing point. The cantilever beam of motion-sensing is also closed in this setting.

For the Model 753 transmitters, the mechanical actuating device is a dual bellows assembly enclosed by a set of two pressure housings. The structure comprises of two interconnected bellows, a center block, overrange valves, a temperature compensator, a strain gage installation, and distance springs. The inner volume of the bellows and center block is filled and sealed with a clean, non-corrosive, non-conductive liquid with a low freezing point. The cantilever beam of motion-sensing is also closed in this setting.

WHY Controls Supply Chain

- • Over 50 years of industry knowledge

- • Fast customer service; response within 15 minutes

- • Best price quality ratio

- • We facilitate the total procurement, purchase and engineering process of our customers

PARTS