Description

SPECIFICATIONS

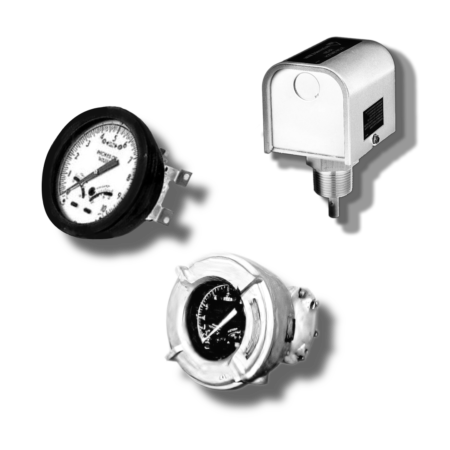

274A Remote Pneumatic transmitter

Changes in DP are mechanically transferred to the flapper, which includes a tiny constant-feed nozzle. Any shift in the location of the flapper will immediately alter the stress of the nozzle, which in effect regulates the behavior of the controlled2-valve relay to boost or reduce the stress of the input water. A calibrated bellows installation actuated by the input stress helps to reposition the flapper system and establish a state of equilibrium-in this way, the input air pressure differs in direct relation to the differential stress given to the tool or in immediate ratio to the flow rate.

Changes in yield stress do not affect the relay and this leaves it feasible to keep practically steady nozzle stress at any input stress. The working span can be continually adjusted from 100-20 percent of the DP spectrum. Thus a device with a differential strain spectrum of 0-100 “w.c. can be adapted to provide a 3-15 PSI (207 mbar-1 bar) yield message (immediate or inverse) for any period of 0-20” w.c. Range to 0-100 “w.c. (0-50 mbar to 0-248 mbar). The operating span can be shifted anywhere within the range of the differential pressure unit to suppress up to 80 percent of the range.

WHY Controls Supply Chain

- • Over 50 years of industry knowledge

- • Fast customer service; response within 15 minutes

- • Best price quality ratio

- • We facilitate the total procurement, purchase and engineering process of our customers

PARTS