Description

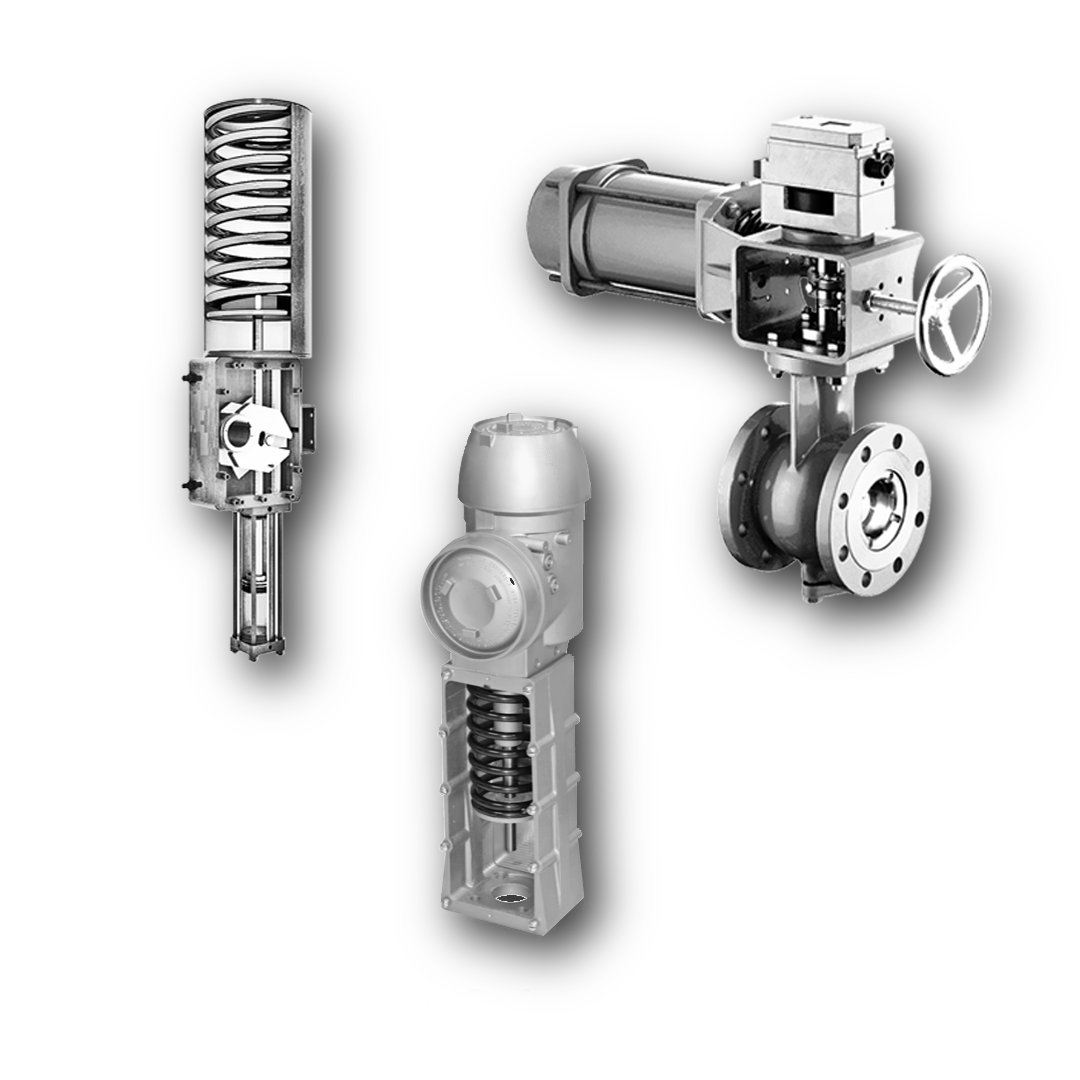

The following features are included in PneuMaster pneumatic diaphragm actuators: rising stem for visible indication of valve position, rising stem for visual indication of valve position, rising stem for visual indication of valve position, rising stem for visual indication of valve position, It’s light weight, which makes it simple to install and maintain. In severe conditions, the non-elastomeric bonnet seal provides exceptional sealing. Molygard wiper rings prevent stem galling and foreign particles from entering the actuator body and harming the dynamic seal system during operation. Overpressurization is prevented by an external safety release mechanism. Actuators are electric-powered devices that allow pipeline operators to operate valves. Electric, air (pneumatic), or flow power (hydraulic), which in our instance is gasoline or gas, can all be used. Two types of actuators are available: temporary and rotating. Gas-over-oil actuators move the mechanics of the actuator by suspending the high pressure gas in the pipeline with a hydraulic fluid. Double-acting gas-over-oil actuators are the only ones that can be used. A power source provides electricity to electric actuators like a battery. Precision control of product flow through valves is critical in the oil, gas, and petrochemical industries, and the valve actuator is responsible for this modulation.