Description

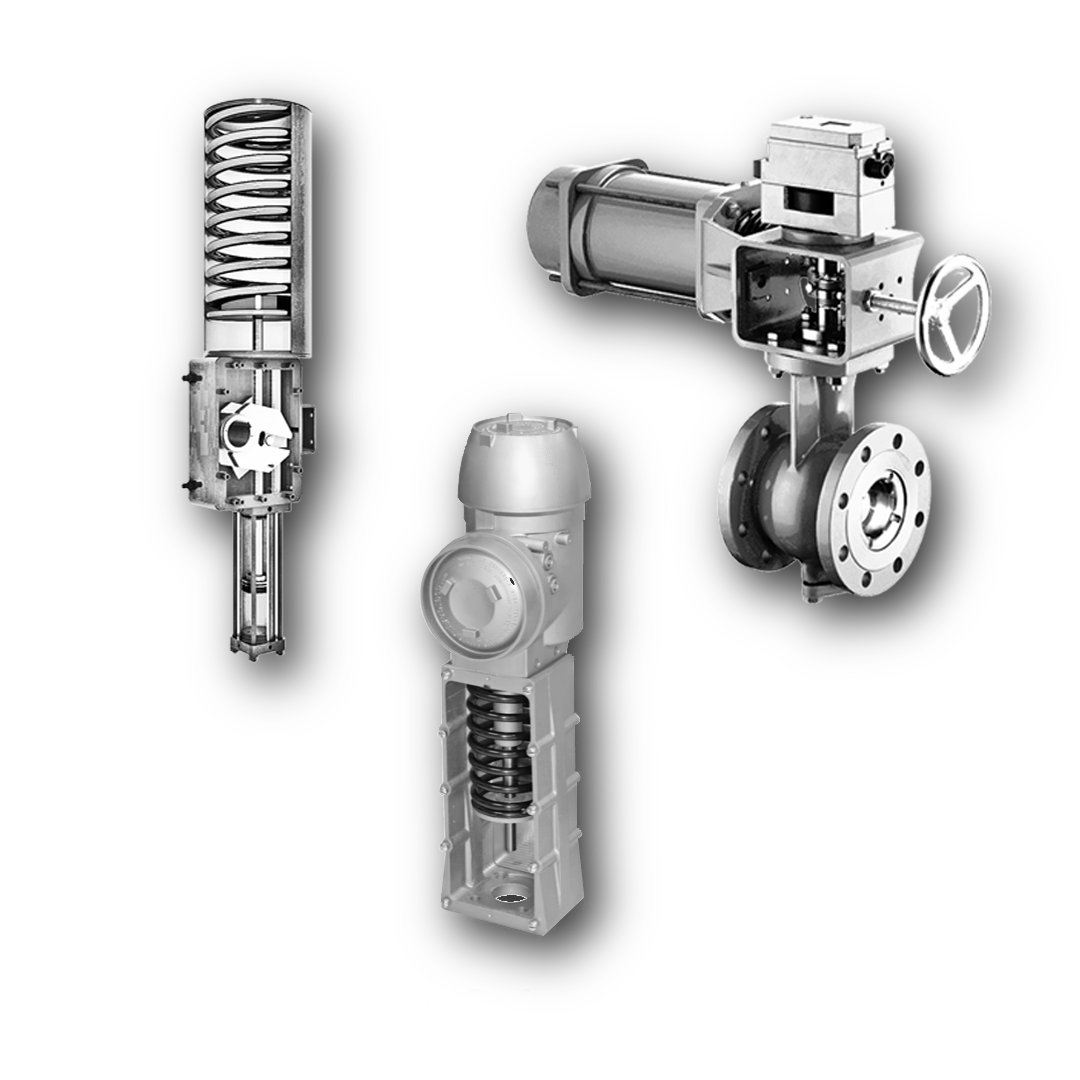

API Spec 6A actuators for use with 1 13/16- through 6 3/8-in nominal gate valves, API Spec 6A F, PR-2 qualified, API Spec 6A F, PR-2 qualified, API Spec 6A F, PR-2 qualified, API Spec 6A F, PR-2 qualified, API Spec 6A F, PR-2 qualified, API Spec 6A F, PR-2 qualified, Temperature rating: –20 to 250°F [–29 to 121°C]; other temperatures available; 13- to 17-in standard diaphragm sizes for these valve groups; 270-psi [18.6-bar] maximum operating pressure; 450-psi [31-bar] test pressure; standard 1/2-in-NPT inlet port; standard 1/2-in-NPT inlet port; standard 1/2-in-NPT inlet port; standard 1/2-in-NP There are many choices and accessories to choose from. Standard stem and bonnet material, PSL 1, 2, 3, and 4 available, standard bonnet backseat test port given, standard packing leak indication port provided are among the bonnet requirements. Actuators are devices that enable pipeline operators to control valves using an electricity source. It is possible to utilize electric, air (pneumatic) or flow power (hydraulic) which is, in our case, petrol or gas. Temporary and rotational actuators are split into two kinds. By suspending the high pressure gas in the pipeline via a hydraulic fluid, gas-over-oil actuators move the mechanics of the actuator. It is only possible to have double-acting gas-over-oil actuators. Electric actuators such as a battery are powered by a power source. In oil, gas and petrochemical sectors, precision control of product flow through valves is important and the modulation is reliant on the valve actuator.