Description

SPECIFICATIONS

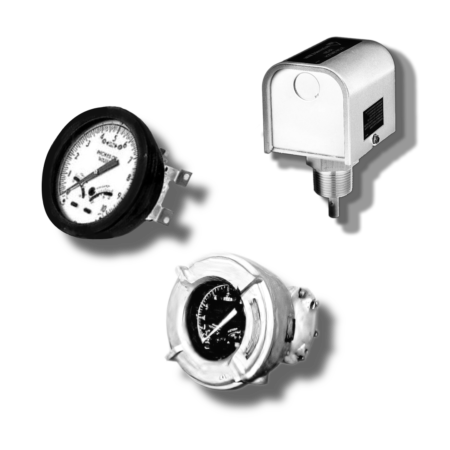

224A dp unit

Model 224A DPU is a dual bellows instrument in charge housing. The dual bellows setup consists of two reverse fluid-filled bellows, center block, coil springs, overrange valves, and torque tube assembly. The pressure housings are connected by pipe or tube to the primary device in the system. With the lowest stress in a linear route, differential strain variations within energy housings cause the bellows to expand or split towards the underside. When the spin wheel is transmitted to the torque tube engine, the linear motion of the bellows is converted into angular rotation and this mechanical movement activates the surveillance scheme.

The process monitoring tool associated with torque tube installation can be an indicator, button, receiver, camera, or other process control unit. Compared to method assignments, the M224A DPU studies surface stress (DP) in a method scheme and produces a mechanical message running on process monitoring instruments and method power devices. High-pressure (HP) transport is connected by pipe or tube to the primary high-pressure device. Conservation of low-pressure (LP) is connected to the primary low-pressure palm device.

WHY Controls Supply Chain

- • Over 50 years of industry knowledge

- • Fast customer service; response within 15 minutes

- • Best price quality ratio

- • We facilitate the total procurement, purchase and engineering process of our customers

PARTS