Description

SPECIFICATIONS

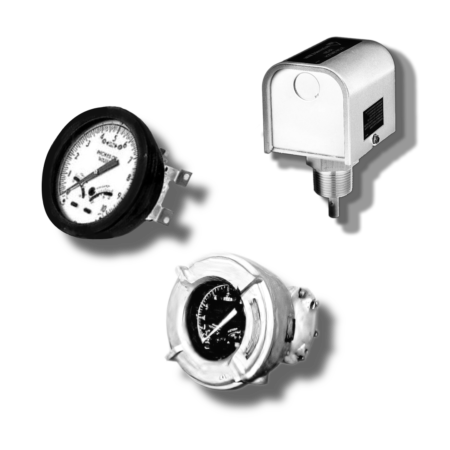

226 dp indicator

The DPU thrust pipe shaft is linked to the signaling mechanism’s motion supporter rod. In reaction to the differential stress introduced, the torque tube rotor rotates. The torque tube belt motion is transferred through the motion supporter frame and the related system to place the identifying pointer at the place on the index scale closest to the differential stress felt by the DPU.

A polyethylene sac is used to safeguard the tool from contamination for applications needing unique cleaning / precautions. This bag should only be removed under conditions of extreme cleanliness. M226 checks the ride elbow for torque tube connection for tightness by introducing torque created by the DPU to a fixed drive elbow. Pressure should be implemented gently as torque is transferred to the link through the torque tube ride shaft and not the torque tube itself.

WHY Controls Supply Chain

- • Over 50 years of industry knowledge

- • Fast customer service; response within 15 minutes

- • Best price quality ratio

- • We facilitate the total procurement, purchase and engineering process of our customers

PARTS